WhatsApp)

WhatsApp)

Pebble mills also known now as ceramic lined mills are a type of ball mill and are used in the size reducing or milling of hard materials such as minerals, glass ...

MSC,。 ==> Main Ship Equipments | Equipment Types | Main Marine Manufacturers

Code. Description. CA1. Analytical . CA1a. Both Conventional Spectroscopic. CA1c. Qualitative. CA1d(i) Hydrogen, Oxygen, Nitrogen content in metal sample

The history of technology, history of science, history of inventions, the scientific revolution, the industrial revolution, the internet, space, communications ...

Our Metallurgical Division offers the Mining Industry a full range of services from bench scale testing to continuous pilot plant operation. We offer a complete ...

Size Reduction Milling From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies.

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals ...

Plate Designs. An extensive assortment of Attrition Mill plate designs are available for diverse application requirements. Optimum plate style for specific ...

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

2 HPGR High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

MILL SYSTEMS Main Features Proven Reliability 25 years design and operating experience Over 425 units worldwide Cost Savings Reduced specific power

SPECIALIZED APPLICATIONS The Micronizer''s innovative design and fluid energy system enable numerous specialapplication possibilities for basic grinding, such as:

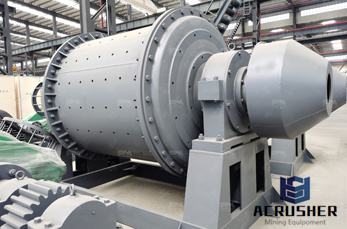

Size Reduction. Tumbling Steel Ball Mills and Ceramic Lined Mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a ...

particle size distribution effects that should be considered when performing flotation geometallurgical testing % %

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Advanced Classification System ™ Ultra sharp top size cuts. Fine particle cuts from 500 microns down to 7 microns; Extremely high product yields.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Welcome... SWECO is the world leader in particle separation and size reduction solutions offering a full line of separation and grinding equipment as well as screen ...

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

1 Minerals Processing Solutions Automation Get the most out of your mineral processing plant

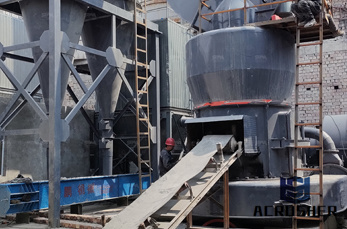

LM Vertical Grinding Mills. It has application in metallurgy, construction, and mining... Learn More; MTM Trapezium Grinder. MTM Medium Speed Trapezium grinder is a ...

Multotec supplies the largest range of coal centrifuges, in basket diameters 800 to 1 650 mm. Vibrating and screen scroll centrifuges for coarse and fine coal.

The ability of a mineral to float depends upon its surface properties. Chemical modification of these properties enables the mineral particles to attach to an air ...

1 AN OVERVIEW OF LIME . SLAKING AND FACTORS THAT . AFFECT THE PROCESS. By: Mohamad Hassibi . Chemco Systems, November 1999 . Revised: .

WhatsApp)

WhatsApp)