WhatsApp)

WhatsApp)

Process Optimization in Cement Industry Download ... ball mill which is the main component of the manufacturing process. Therefore ball mills are used for ...

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

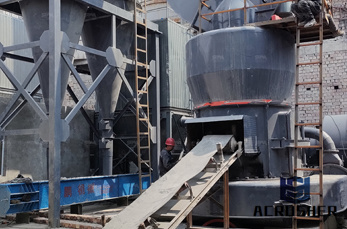

A ball mill is a type of grinder used to grind and blend ... Ball mills are used extensively in the mechanical alloying process ... Cement mill; Vertical roller ...

Appliaction of ball mill How is ball mill working? Ball mill technical data. Model ... According to the process condition: 800: 137: Ball mill structure. Hopper ...

Optimizing the operation of the cement mill | Industrial. Ball mills account for the majority of all mills in cement plants and therefore the Optimizing the ...

Discover used Feeder, Miscellaneous for sale at Perry Process.

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Ball Mill Process | Crusher Mills, ... This study evaluated the tribological processes in a ball mill using cement grinding mills at Benue cement company Gboko, ...

The history of the cement manufacturing. The word cement caementum from Latin means gravel and of gravel and flaky cement history can be traced back to,

The XRDMill McCrone was specially developed for the preparation of samples for subsequent xray diffraction (XRD). Contact us for details!

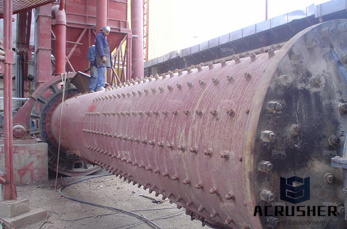

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Ball mill. I have a ball mill grinding cement, Ø3,8 x 14 m, close ciruit process with OSEPA separator N2000. Ball charge of compartment I is Ø 90, 80, 70, 60 mm ...

Ball Mills of Vipeak for qualigied products and superior service,Vipeak gives you the best Ball Mill,Superfine Ball Mill,Cement Mill,Cement Grinder, ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Machinery and Equipment buys and sell Used Ball Mills for mining and minerals applications, as well as smaller batch mills for chemical applications. View our online ...

Ball Mill is widely used in ore grinding, cement mill making, mineral ore dressing

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ...

Most cement is currently ground in ball mills and also vertical roller mills which are ... Ball mill Process Flow of Cement Making Plant ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

CEMENT MILLS Twochamber ball mills for the cement industry are available in ... If the process material is moist, cement mills can also be confi gured with a drying ...

Used Roller Mills – Brunkan Equipment. Check out our used equipment and rentals! Home; Equipment Rental ; Used Equipment For Sale . ATVs; Ag Feed Equip. Blowers; .

Cement Mill Process, ... alibaba express china cement ball mill process, cement ball mill for sale. US / Set . 1 Set (Min. Order)

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

WhatsApp)

WhatsApp)