WhatsApp)

WhatsApp)

The rolling defects are mainly two rolling defects internal structural rolling are main category of rolling defects surface defects are provided from impurities and inclusion in the material surface, roll marks, dirt, rust and other cause related to prior treatment and working of metal.

Metal forming processprinciple it is a process in which the forces are applied on the material such that the stresses induced in the material are greater than the yield stress and less than the ultimate stress so that the plastic deformation produced in the material will be used for changing the shape of the component is called as metal forming process.

There are basically two groups of grinding mill with a high profile and those with a low high profile liner is designed to give the media the higher type will be used in mills that are designed for primary grinding and as a result require the impact of the higher mills working as the secondary portion of a grinding circuit will utilize the.

Compression garments are touted as the secret to increasing muscle power and optimizing athletic performance science or hype the theory behind compression clothing is that it helps blood flow through the muscles in the part of the body wearing the garment youre wearing compression.

This invention relates to pilger rolling mills, particularly pilger coldrolling mills, of the kind in which the billet is rotated at a stage in the rolling process through a worm and wormwheel arrangement in which the worm is moved longitudinally to effect operation by a cam follower bearing on a rotating cam disc.

Ring rolling as thickwalled ring is compressed, deformed metal elongates, causing diameter of ring to enlarge hot working process for large rings and cold working process for smaller rings products ball and roller bearing races, steel tires for railroad wheels, and rings for pipes, pressure.

Rolling of metal auxiliary operations used in connection with methods or mills for making semifinished products of solid work roll being supported by two rolls only arranged symmetrically with respect to the plane passing through the working rolls 201301 b21b alternatively.

Grinders like hammer mills, rollingcompression mills, tumbling mills, are used for intermediate and fine size grinders like hammer mills, agitated mills, fluidenergy mills, basic motive behind performing the sizereduction is to make too large to be used solid materials usable.

Hot rolling is an effective way to reduce grain size in metals for improved strength and structures of ingots or continuous castings are converted to a wrought structure by hot sheet leveling rolls a method of roller leveling to flatten rolled sheets 15.

The compression molding is mainly used for thermosetting plastics thermosets and some thermoplastic can be produced in this compression moulding materials have preform for before form of granules, putty like mass into thermosetting is used to high wight compression moulding products can be produced.

Thank you for a2a to metal rolling is one of the most important manufacturing processes in the modern large majority of all metal products produced today are subject to metal rolling at one point in their

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal has the features of simple structure, low cost of manufacture and roller mill has many different forms, but it works basically the same.

For embossing, rolling sheet or foil, making wire for filigree, theyll work just have used a karat rolling mill for several have not done any work with mokume billets, but i have used it to roll 18k red gold ingots, which are hard as nails, and require some serious compression to roll without cracks karat held.

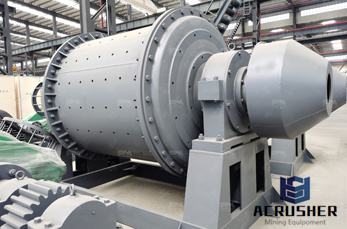

Several types of ball mill differ to an extent in their operating also differ in their maximum capacity of the milling vessel, ranging from litres for planetary ball mill, mixer mill or vibration ball mill to several 100 litres for horizontal rolling ball mills.

The use of oilair systems to lubricate the roller bearings of working rollers in hotrolling oils, in place of plastic lubricants, will change the conditions at the contact surfaces 1.

In most cases, metal is cast or forged into the desired shape after it is made malleable through the application of working refers to the process of strengthening metal by changing its shape without the use of heat.

Utama rolling compression is an indirect compression rolling mills can be classified according to the arrangement of stands or basic understanding of the mechanics of rolling mill strength in rolling mills very high pressure is applied, especially between work rolls and backup price.

Modern, efficient cold rolling mills can roll pickled sheets or strips at speeds of up to 4 ms and tandem mills that are continuously working can produce up to million tons of cold rolled steel advantages of cold rolled products have the following advantages over hot rolled greater dimensional accuracy.

Compression garments are touted as the secret to increasing muscle power and optimizing athletic performance science or hype the theory behind compression clothing is that it helps blood flow through the muscles in the part of the body wearing the garment youre wearing compression.

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and is an energy efficient alternative for a ball

The planetary rolling mill lorn, 1 university at kingston survey was made of the available literature on planetary rolling and planetary rolling this a distillation of information was made which included a description of the mill and the material.

Flywheel is mainly used in engines and fabricating machines rolling mills, punching machines, presses etc to get uniform speed during its is also used as a part of clutch mechanism and fluid drive clutch assembly is mounted on the flywheel and rotates with it.

Types of rolling techniques | products are then passed through rollers at room rolling mills are similar to that used in hot cold rolling process has the advantage of providing close dimensional tolerance up to cold working does not need expensive tools and hence.

The hot rolling mills, which will roll the steel in tandem with one workhorse roughing mill has 135 wide rolls for rolling broadside as the first roughing mill is commonly called to make a slab 5,000 hp motor drives 42.

WhatsApp)

WhatsApp)