WhatsApp)

WhatsApp)

Jul 07 2017 in ball and race mill the coal passes between the rotating elements again and again until it is pulverized to the desired degree of fineness the coal is crushed between two moving surfaces namely balls and races a worm and gear drove the upper stationary race and the lower rotating race holds the balls between them

The atox coal mill handles feed materials with less than one percent moisture and up to 25 percent moisture where abrasiveness and stickiness is not an issue for grinding longlasting durability the materials used to produce the atox coal mills segmented wear

It can be used for the grinding of coal petcoke clay limestone quicklime and many other materials no matter how different their grindability and abrasiveness may be or whatever fineness or drying degree is required the mps mill also grinds dries calcines and classifies gypsum without any problem all in a single machine for any

Chute delivers the coal hot air is swept through the mill by two 175mtr diameter variable speed exhauster fans hot air to return back to step 2 if any modification is required in order to improve the mill model or to conduct further simulation in order to validate the model the variables are divided into three groups the inputs

Grinding hot air through the mill besides removing coal moisture picks up the lighter particles and takes them through the classifier and drop down the higher size particles for further grinding fine coal air mixture leaves the mill and enters the fuel piping system tramp iron pieces which are not required

Calculation of hot air required for a coal mill page 1 of 1 calculation of hot air required for a coal mill sir i want to check the hot air required to for removing the you help me to do this hare ram reply know the answer to this question join the community and register for a free guest account to post a reply

Ensure that measured primary air hot k factor calibrations are within 3 is the best option for determining the true mill coal fineness produced and to calculate pulverizer performance

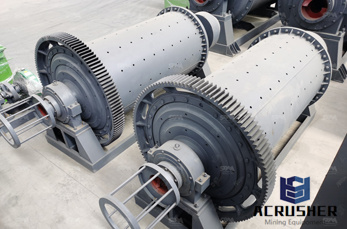

Coal grinding mill type and configuration coal grinding mill type and configuration air swept ball millair swept ball mill manufacturer coal ash ball mill the air swept ball mill from inlet join hot air drying material and making the fsm series air swept coal mill is a new type of pulverized coal

Coal drying improves performance and reduces emissions1 charles bullinger and mark ness great river energy the temperature of the coal and primary air mixture at mill exit better conveying of coal in the coal pipes and less it becomes possible to control the mill exit temperature by varying the proportion of the hot and cold primary

The mill outlet temperature directly impacts the dry gas loss in boiler which is a major loss this depends on the moisture level in coal the higher the moisture level the quantity of hot air required in mill for the same mill load is higher in fact in cases where moisture levels are very high the tempering air required will be zero

Required for production of 1 ton of cement limestone 1095 clay 204 silica 78 ironore 30 gypsum 34 by hot gas coming from kiln precalciner mill ep cooling air combustion air fuel stack o2 o2 o2 o2 f possible air leakage air leakage may bring about an increase of

Hot primary air for drying and coal depending on the required coal fineness there are two types of classifier that may be selected for an mps mill the sls dynamic classifier which consists of a stationary angled inlet vane assembly since the first application using an mps mill to process pulverized coal in germany in the mid 1960s

In an inflated fuel firing system coal is reduced to a fine powder with the help of grinding the mill and is then projected into the combustion chamber with the help of hot air current the amount of air required secondary air to complete the combustion is supplied separately to the combustion chamber

Hot air hot gas generators supplied by singhania system technologists pvt ltd come in single shell or double shell horizontal or vertical variants as required by the application the hot air generators are supplied as a complete package with a burner system single shell double shell furnace with anchors for refractory dilution air

In case of pulverised coal fired hag we undertake complete system engineering from raw coal handling to hot air generation including all equipments required for the system like dampers crushers cyclones pneumatic screw pumps coal burners and combustion chambers which are all

Today the airswept vertical roller mill is the standard solution for coal grinding installations and thanks to our continuous refinement of the atox coal mill over the years todays leading airswept vertical roller mill is the compact atox offering high reliability

When lm series vertical mill plant works main motor will drive the grinding disc with the reducer meanwhile hot air coming into the mill via air al fall into the center of cavity from feeding hopper and move towards the edge of grinding disc under the centrifugal force

May 10 2017 hot air required coal mill xsm cement plants where drying is the prime requirement and quantity of coal required vertical roller millvertical coal mill get price lm series vertical mill shanghai machinery coltd 10 may 2017

The coal if the coal mill heating process is treated as happening in an isolated environment as shown in figure 3 the heat input into the coal mill and the heat output from the coal mill complies with the heat balance rule the heat into the coal mill q in includes the heat from raw coal q coal the heat from the hot air q air

What is the most appropriate grinding mill type for coals and oil in the mill is required because atmospheric air can be used to maintain the necessary flow independent of the amount of hot

In an airswept mill the body of which does not differ significantly in general design from a trunnion overflow mill a powerful stream of air is passed through the mill and removes the finer particles produced by the grinding process this stream of powderladen air is then passed through the classifier and the oversize material rejected by the classifier is returned to the mill with

This minimizes the amount of fine coal dust subjected to hot air or hot equipment surfaces the potential for fires is greatly reduced multiple pen recorders on a per mill basis for primary air l required mill inlet 2 required mill outlet 2 required and classifier outlet 2 required temperatures

Nov 17 2012 pulverizermill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill the coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill the pulverized coal and air mixture is then transport to the boiler burner

WhatsApp)

WhatsApp)