WhatsApp)

WhatsApp)

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Wet and semiwet process cement kilns ... It is this thin layer of water that allows the slurry to flow. As the separation of particles increases with increasing ...

Executive Summary Cement, Lime and Magnesium Oxide Manufacturing Industries iii of energy. The secondary processes of lime slaking and grinding can also be of ...

02. Blended Cement The use of blended cements is a particularly attractive efficiency option since the inter grinding of clinker with other additives not only allows ...

This produces a powder that will react with water and change from a paste or liquid solution into a solid mass. The finer the cement clinker is ground, the faster the ...

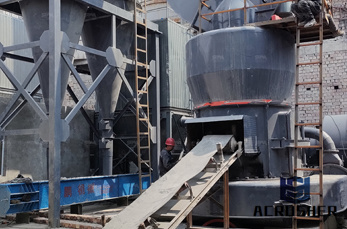

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste ...

TECHNOLOGICAL UPGRADATION OF CHUNAR CEMENT GRINDING UNIT,, CHUNAR CEMENT FACTORY (A Unit of Jaiprakash Associates Ltd. India)

PMTZyklontechnik GmbH 3 Alternative fuel ALTERNATIVE FUELS IN THE CEMENT INDUSTRY 1 INTRODUCTION The production of Portland cement requires a high degree .

UNITED NATIONS INDUSTRIAL DEVELOPMENT ORGANIZATION Global Industrial Energy Efficiency Benchmarking An Energy Policy Tool Working Paper November .

Free of charge: Ukrainian Exporters Database offers free access. Search guide: Search data by industry sector or/and keyword. Feedback: If you did not find specific ...

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Advanced Cyclone Systems is focused on the development of high efficiency air cyclones worldwide. These dust collectors are an exceptional alternative to bag filters ...

The potential opportunities for improving energy efficiency and lower CO 2 emissions in raw material generation and production of concrete are smaller than in cement ...

New type of clinker significantly reduces CO 2 emissions. Cement clinker production is very energyintensive — around tonnes of CO 2 on average are released per ...

Spare Parts. KHD Humboldt Wedag offers excellent local After Sales services for all KHD supplied equipment, from the acquisition of spare parts, to technical ...

Ball Mill, Grinding Mill, Ball Mill . Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to ...

I am assisting a waste to energy technology company to enter into the cement industry. The plant requires waste input such as municipal garbage, including ...

Fact Sheet RECYCLING AND RECOVERING POLYURETHANES Energy Recovery from Flexible PU Foams INTRODUCTION Polyurethane flexible foams exist in many forms and .

Coal is a combustible black or brownishblack sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms ...

The online version of Fuel Processing Technology at, the world''s leading platform for high quality peerreviewed fulltext journals.

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power...

Global Carbon Dioxide Emission from Cement Production Process In this paragraph we provide an estimate of both process and energy emissions from global cement

Coal is the fuel that undergoes least human intervention before use: it is burned in essentially the same condition in which it is dug from the ground.

( TOWARD A SUSTAINABLE CEMENT INDUSTRY ) iv Industrial ecology Framework for improvement in the efficiency of industrial systems by imitating aspects of natural ...

WhatsApp)

WhatsApp)