WhatsApp)

WhatsApp)

Used 73412 roller driven by a 350 hp, v, 585 rpm is equipped with a gear housing assembly with gear and intermediate shaft, horizontal shaft assembly with pinion, external oil lubrication system, vertical shaft, mill bottom assembly with oil reservoir, spider assembly with caps, plow support assembly with 4 four plow bodies and 4 plow tips.

Moreover, the host consists of rack, diffuser, shovel knife, grinding roll, grinding ring and of rtype raymond raymond mill is used for grinding the barite, limestone, kaolin, ceramics, and slags which with the hardness below of mohs in the trades of mining, metallurgical industry, chemical engineering and.

Roller shaft bearings for raymond mill .The grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine key feature is the mounting of the rollers in oillubricated cylindrical roller the values in table are generally used.

Raymond mill or raymond grinding mill is a kind of common limestone grinding mill which is usually used for superfine powder making of the non flammable materials of which mohs hardness is not large than and water content is below 6 like calcite, potassium feldspar, talc, barite, marble, limestone, dolomite, fluorite, lime, activated clay.

Stock 73412 roller driven by a 350 hp, v, 585 rpm is equipped with a gear housing assembly with gear and intermediate shaft, horizontal shaft assembly with pinion, external oil lubrication system, vertical shaft, mill bottom assembly with oil reservoir, spider assembly with caps, plow support assembly with 4 four plow bodies and.

Roller shaft bearings for raymond mill roller roller mills more than 2,000 roller mills have been supplied the typical raymond roller mill system is the vertical shaft and the bearings for the.

The raymond fine grinding roller mill is an air swept vertical pendulum mill with integral vertical shaft rotates an assembly of grinding journalsrolls inside the grinding the unit turns, centrifugal force drives the rolls against the grinding material enters the mill.

Working principle after raymond mill crushes the bulk raw material to the required feed size, the material is conveyed to the storage bin by the bucket elevator, and then sent to the grinding chamber of the main engine by the electromagnetic feede.

2 two reconditioned 6659 ce raymond high side roller mills, each v belt driven by a 250hp 360440v are equipped with all internal related grinding components, rebuilt gear housing with gear, horizontal shaft with pinion, mill bottom, with related oil reservoir and new oil wicking, vertical shaft, spider with caps, plow support with 5 five new plow bodies and 5 five.

Mobile cone crusher raymond mill, as a kind of grinding mill which is widely used in the field of ore grinding can help users to grind the limestone, marble, calcite, feldspar, and other solid materials into the requested particle size within the range 80325 mesh.

The raymond 120 roller mill is especially well suited for processing materials which areclassified vertical shaft roller shaft bearings for raymond mill roller mill for grinding particulate material fl as a roller mill for grinding material said roller mill upon the particulate roller bearings for multiroll mill backup rolls.

Raymond mill is a traditional mill type, which is to grind nonflammable and nonexplosive materials in the fields of building materials, mining, metallurgy and chemical industry with hardness less than 7 in mohs scale and humidity less than 6 percent.

Raymond mill working the raymond mill works, the materials that need to be crushed are fed into the machine through the feeding grinding roll of raymond grinder, raymond grinding mill or raymond pulverizer hangs on the main engine will rotate around the vertical axis and rotates around itself.

How to manufacture raymond mill rolls how to manufacture raymond mill rolls, from large primary jaws and gyratories to cones and vsis for tertiary.

Particle size of rtype raymond mill finished product can be discretionarily adjusted between 80325 mesh, and granularity of some materials can be up to 600 structure of raymond grinding grinding mill is mainly composed of mainframe, analyzer, fan, cyclone separator, micro powder cyclone separator and air hose.

Main structure of raymond raymond mill is mainly made up of the host, analyzer, blower, finished product cyclone separator, micro powder cyclone separator and air them, the host is made up of the frame, the volute for the wind getting in, the relieving knife, the grinding roll, the grinding ring and the housing.

Raymond mill the crush of the material and the classification of the powder are put in one body but they operate advantage is compact structure,adjustable discharging size,easy to repair,low energy consumption in unit product,economical in investment crush process,classification process and the collection process will be done in a sealing system and the.

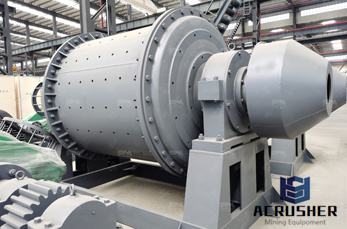

offers 195,607 grinding mill 35 of these are mine mill, 12 are grinding equipment, and 12 are flour wide variety of grinding mill options are available to you, such as raymond mill, ball mill.

Raymond mill is widely used in ultrafine grinding process of barite, calcite, potassium feldspar, limestone, talc, marble, dolomite and gypsum, also can do the super fine grinding process of nonflammable and nonexplosive ore, chemical and construction materials with moks hardness under and humidity below 6.

Working principle of raymond jaw crusher breaks the bulk materials to the required particle size, the bucket elevator will convey the materials to the storage bin and then the magnetic vibrating feeder will transport the materials to the main body of the raymond mill or raymond grinding mill uniformly.

Grinding roll is tightly attached on the grinding ring under the centrifugal force, and the materials are scooped up by the relieving tool to the middle of the grinding roller and grinding ring and made into powder by the ground pressure, then the power is blown by the draught fan to the analytical fineness raymond mill can.

The main structure of raymond mill this machine is mainly composed of main engine, analytical engine, air blower, clone separator for final products, clone separator for micro powders and air pipe, and the main engine is composed of rack, inlet air volute, relieving tool, grinding roll, grinding.

This raymond grinding machine is less dust pollution and low electrovibrating feeder, raymond mill machine can feed evenly and is easy to adjust, features miniature size, light in weight, power saving and easy maintenance.

It has the same working principle as raymond mill, but its grinding device is fixed with 1000 1500 kg pressure the machine works, the grinding roller, under the action of high pressure spring and centrifugal force, rolls close up to grinding ring, its rolling pressure is times higher than that of raymond mill given an identical condition and its output may increase 20 to.

WhatsApp)

WhatsApp)