WhatsApp)

WhatsApp)

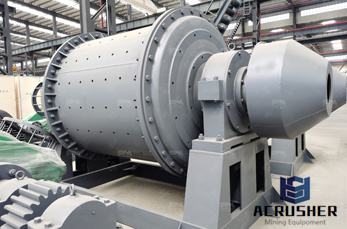

A ball mill is a type of grinder or mill used to mill the materials into fine powder. This ball mills are especially useful for grinding hard materials.

Model Predictive Control for SAG Milling in Minerals Processing | 3 ... Model Predictive Control for SAG Milling ... while keeping the process stable. Ball mills ...

The modelling of the mechanical alloying process in a planetary ball mill: comparison between theory and insitu observations P. Le ... Planetary ball mills ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process Control

Autogenous mills, semiautogenous mills ... The resulting global know how of process and plant technology, ... and big ball mills....autogenous and semiauto

· Ball Mill Working principle: When the ball ... in small and medium size ball mills to ... of the ball mill in the grinding process?

What is ball milling? A ball mill is a type of grinder used to grind materials ... Drum ball mills ... process Tip of iceberg ...

Cement grinding Vertical roller mills versus ball ... cement ground in OK mills similar to those for cement ground in ball mills ... In the grinding process heat ...

How Does Ball Mill Work? | working principle of ball mill . How Does Ball Mill Work? ... Type of ball mills, ...

in modeling and control of the grinding process in industrial ball mills. ... study of AlNiMo alloys obtained by mechanical alloying in different ball mills" (PDF).

Twochamber ball mills for the cement industry are available in ... If the process material is moist, cement mills can also be confi gured with a drying chamber.

Nanoadditives SiO2 and TiO2 in process fluids (PDF . ... is with stable and reliable working condition ball mill and wet ball mills for choice. Ball Mill Working .

Grinding in Ball Mills: Modeling and Process . Semantic Scholar. in modeling and control of the grinding process in industrial ball mills. . (coefficient of ...

Process. 48(2), 2012, 329–339 ... determining the optimal ball charge in mills. ... The optimal ball diameter in a mill 333 The grinding efficiency of the narrow ...

A mathematical analysis of milling mechanics in a planetary ball mill Chattopadhyaya, ... of this milling process in terms of ball velocity, frequency of

on ball motion in mills using the discrete element ... A ball mill is one kind of grinding machine, ... and frictional force working between particles that are

Some devices, such as ball mills, are more suitable for coarse materials. These mills ... process 3. Low power consumption 4. Mills come jacketed for heating

FLSmidth ball mill for cement grinding. ... For ball mills operating in closed circuit, the circulation load is monitored by weighing the flow of reject material

6 Shell Supported The everincreasing demand for larger diameter mills meant that designers had to employ new methods to compensate for the increased shell

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert "Bob" Schilling Presented at the .

Working In case of ... the mechanical alloying process ... of ball mill called a planetary ball mill. Planetary ball mills are smaller than common ball mills and ...

... via a hand crank), working animal (, horse mill), wind or water ... and can be used after ball mills in a grinding process. Like ball mills, ...

Attritors and Ball Mills How They Union Process 9 May 2000 ... A useful and simple equation describing the grinding momentum is M x V (mass x ...

water jacketed hammer mill principle and working. Impact, attrition, hammer mills, ball mills ... The working principle of Vertical Roller Mill is based on two ...

WhatsApp)

WhatsApp)