WhatsApp)

WhatsApp)

Coal fineness is a relative measurement of particle size distribution typically applied to the product leaving a pulverizer standardized wire mesh screens are stacked and used to shake down samples

Instead of maximizing coal fineness improvements only the dynamic classifiers can be rpm is programmed to follow mill coal flow to obtain a desired fineness vs mill load rela tionship manual override with manual control of classifier speed from the control room is

How to improve coal fineness in xrp 763 coal mill how to improve coal fineness in xrp 763 coal mill how to improve coal fineness in xrp 763 coal mill can provide the proper grinding measure to all kinds of methods get price and support online coal properties and its influence on boiler pankaj

Coal mills for cement plants coal grinding mills loesche performance factor as well as the product which is influenced by factors of grindability moisture and fineness the required gas stream is decisive for the housing dimensioning of mill and classifier highlights

Coal mill fineness trouble foxing heavy machinery coal mill fineness troubleit will also have a very high influence by operating parameters like coal fineness burner air swirl maintained in the burner coalair mixture velocity etc coal burner damage during operation how and why hence checking operating mill fineness

The end result is that pulverizer fineness at the lower loads increases on pulverizers with 75 passing 200 mesh fineness at full load minimum load fineness can be as high as 85 or more in some instances an excessive quantity of finely ground coal particles on the bowl acts as a powder lubricant between the roll and bowl

Coal fineness of bowl mill xrp 763 aiba xrp 763 mill coal mill xrp operation design parameters how to improve coal fineness in xrp 763 coal mill bowl mills the raw coal so that the pulverised product at desired hp or xrp coal mill batchingplantga hp or xrp coal mill drawing of xrp 783803 coal mill bharat heavy electrical ltd stone crusher

Controlling factors for coal mill fineness bassemgardensbe reason for poor coal fineness in mill sidoo controlling factors for coal mill fineness mobiletelin in this process coal is first pulverized and the fineness achieved is as that of a talcum 4 condenser 10 pulverized fuel mill 16 precipitator of reliability resistance to flow

The adverse effects are compounded because burners having more coal will likely be of lower fineness making it even more difficult to achieve complete combustion in the burner belt zone importance of fineness poor coal fineness often yields poor distribution as large coal particles air mix to form a 2 phase mixture which will not homogenize

33 coal particulate size and fineness figure 7 shows the coal fineness from the sampled particulates of the four pc pipes for the two elevations from mills 20 and 40 respectively according to plant requirements more than 70 by weight of the pulverized coal should be smaller than 75 m

To summarize the coal mill controls they may be divided basically into two major categories 1 to control the quality of coal being sent to the burners located on the furnace walls the word quality here means the temperature and fineness of the pf the set temperature values are dependent on the percentage of volatile matter that exists in the main fuel

Collecting coal samples using an isokinetic probe provides the best data describing actual operating conditions inside the coal pipe source storm technologies inc the isokinetic coal sampling method although more difficult is the best option for determining the true mill coal fineness produced and to calculate pulverizer performance

31 this test method provides a means for assisting in the evaluation of pulverizers and pulverizer systems in terms of fineness specifications it may also be used to confirm the influence of coal fineness on combustion performance and to evaluate carbon loss by consent among interested parties it may be used for evaluation of coal fineness in preparation pneumatic transfer systems etc

Nov 17 2012 mill bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion the mill output can be easily varied as per the turndown ratio from its minimum to maximum load crushed raw coal at a controlled rate is fed into the revolving bowl of the bowl mill

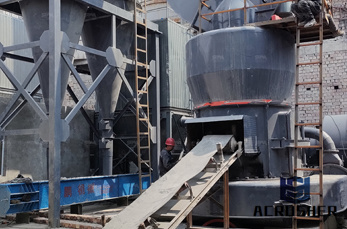

Coal mill is the equipment used for grinding and drying coal with different hardness and it is mainly composed of feeding device principal axis rotating the part transmission part discharging part highpressure starting device and lubrication system it is widely used cement building material thermal power generation metallurgy and chemical industry

Analysis of coal mill fineness coal mill zenith coal mill finenesscoal mill is an important auxiliary equipment for coalpowder furnace it has three methods to crush the coal lump and grind them into powderit is crushing analysis of coal mill fin live chat coal mill fineness astm

Animatioin of solid fuel coal mill in power plantsash ball mill machine in the plant cement factory in raw mill and crushercoal grinding equipment manufacturercoal hammer mill working principle ppt coal mill fineness in thermal power plantcoal mill fineness trouble coal mill model control coal pulverier power plant velbertcoal roller pulverier pdf velbert

Fineness of pulverised coal percentage of coarser particles the mill reject loss depends on the amount of pyrite in coal and the mill operating condition dr v t sathyanathan is a boiler consultant with 35 years of experience in various areas of high pressure boiler trouble shooting he holds a phd in coal combustion in boilers

Coal mill fineness trouble reason for poor coal fineness in mill famvanderjagt reason for poor coal fineness in mill our purpose and belief lm heavy industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of the customers and build bright future with high

Lime slaking mill 911metallurgistwhen mill practice requires that the lime first be slaked and made into a water slurry the design engineer will find a wide

Coal mill fineness trouble how much crusher how to improve coal mill finenesscoal mill fineness trouble posted at apr 29 2014 price 84197how to run a coal fired boiler at the best efficiency boiler efficiency is mainly depended on the amount of losses in the systemhow to effectively improve the grinding fineness of ball mill

Coal mill fineness in thermal power plant nov 17 2012 coal mill pulverizer in thermal power plants specifically fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50 100 and 200 mesh a 70 coal sample passing through a 200 mesh screen indicates optimum mill performance the mill wear and the power consumption are increased

WhatsApp)

WhatsApp)