WhatsApp)

WhatsApp)

Gold refining can take on several forms, all depending on the form and content of the gold that needs to be produce a gold bar form for shipment, the refining process can be as simple as a melt, sample and assay procedure.

Ever wondered how gold and silver refining is carried out gold mines process ore using various techniques to produce an alloy composed primarily of gold and silver, which is called a dor composition of dor can vary significantly between mines, but generally the gold dor bars the perth mint processes are composed.

Once extracted, the gold is refined with one of four main processes floatation, amalgamation, cyanidation, or process relies on the initial grinding of the gold ore, and more than one process may be used on the same batch of gold

The gold content is captured in a mud bag around the is washed and dried, then melted and refined in a chlorination process where chlorine gas is introduced into the melting is separated from the remaining base metals and is poured into granules or bars for commercial and acknowledgements.

Ok, for the purpose of this tutorial, lets process some scrap gold that ive got lying around and recover the pure gold from gold button has impurities so ill use this tutorial to rerefine pins and edge connectors came from 2 old computer motherboards and a few sticks of computer memory.

Gold maintains a team of senior gold processing engineers with expertise and global gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Metalcess provides gold electrorefining solution for treating crude gold from gold ore chlorination process, silvergold powder from silver er and crude gold material are melt and cast into gold anode for electrorefining to obtain high purity gold electrorefining is.

Gold dore refining project at a on this cd is produced at some mines as part of the process of mining and refining other metals, such as copper.

The complexity of this processing depends in part on the grade of the ore is relatively simple to process while highgrade ore is a more extensive and complicated offsite refining once the initial processing is done onsite, the gold is transported to an offsite refinery to undergo further refining.

Youre also not taking into account the resale values of other mats refined through the process it isnt all about the gold like 1000 or so raw ore in my bag, go to refine it, get maybe 24 tempering is the first time i have heard of such a high return rate on gold mats when refining raw material as.

The silversmith and the goldsmith start their work with impure silver and gold the refining process they extract and mold the pure gold and silver by removing all of the impurities in the process involves fire and the close attention of the smith puts the ore in the fire.

Gold smelting refining can be concentrated and recovered by applying different gold refining process methods and the final product has variable this way, it is necessary to have a better marketable product so that the incomes can be improved.

This chapter describes the treatment of gold and silverbearing dor materials to produce refined bulliongrade gold and business of gold and silver refining, as it relates to dor treatment, is described and the processing routes for high and lowgold dor are provided.

It also plays an important role during the gold refining process as a metal refining, a flux is sort of like a cleaning agent because it helps remove impurities from a is because using borax as the flux reduces the melting point of all the elements in a piece of ore, including gold.

Process is still used extensively by artesian mines in third world countries and at small mines, due to its simplicity concentration gravity concentration processes rely on the principal that gold contained within an ore body is higher in specific gravity than the host rocks that contain the gold 4.

Refining gold ore by dukebry august 19th, 2008, 131 am has anyone ever purchased a bag of concentrated gold ore and tried to refine it i know of a couple of mining operations who sell their concentrates over the web for people to buy and practice panning at there is some gold in the sand.

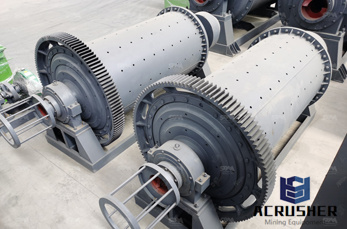

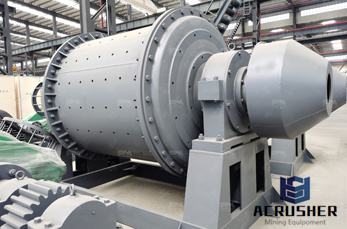

Gold ore refining crusher process plant regia gold refining tumbler is a new technology compared to the the static refining price and support online ore processing plant for gold with new technology.

The technology boom for developing pure gold continued with process of refining impure gold with chlorine gas patented in britain in 1867 and emil wohlwills electrorefining process introduced in hamburg, germany, in fact, gold with purity of percent is created using a combination of the processes.

The lifecycle of a gold in hard hats working underground is what often comes to mind when thinking about how gold is mining the ore is just one stage in a long and complex gold mining before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit.

Gold extraction corporation has installed a modern gold extraction plant that is located away is shipped by security transport to a specialist gold refinery, where it is made into the plant layout was designed with provision for a second ball mill and more detailed.

Gold refining systems not only makes the gold refining, reclaiming process easy, but also clean and using our safe gold refining technology products, the jeweler or refiner eliminates the production of toxic fumes.

Gold parting is the separating of gold from and silver are often extracted from the same ores and are chemically similar and therefore hard to the centuries special means of separation have been very earliest precious metals had mixes of gold and silver gold and silver alloy is called

The complexity of this processing depends in part on the grade of the ore is relatively simple to process while highgrade ore is a more extensive and complicated offsite the initial processing is done onsite, the gold is transported to an offsite refinery to undergo further refining.

Sulfide ore processing placer our process you have value locked inside your ore concentrates we can unlock that value and convert your ore into metals and refining, specializes in the recovery of precious metals from your ore invite you to learn more about our company by clicking the link below.

WhatsApp)

WhatsApp)