WhatsApp)

WhatsApp)

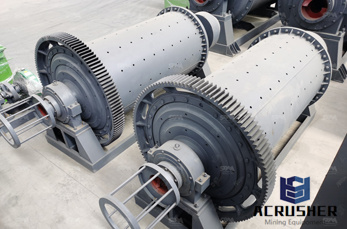

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

KURIMOTO, LTD. Product Information, Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill

FLSmidth ball mill for cement grinding. ... requirements in terms of plant layout, mill drive, lining types and end product specifications, as required.

Arcanol Rolling Bearing Greases For reliable, durable and costeffective bearing arrangements

doc: sti/1489(part1) (part2)/1/ls m ay 2 05 scheme of testing and inspection for certification of portland pozzolana cement according to

Ball Mill For Cement Industry Pdf, process crusher, ... The "work horse" of the cement grinding plant is the twocompartment ball mill,. Read more.

Process Diagonistics Studies for Cement Mill Optimization Holtec diagnostic studies in many cement plants. The paper describes the approach for the process ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

The High Chrome Grinding Ball manufacturer supplying for all the Japanese cement and mining plants. The PREFERRED Global supplier for LAFARGE, HOLCIM ...

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Figure 2: The integrated cement plants and standalone cement grinding plants in the UAE in 2014, colourcoded by installed integrated cement production capacity in ...

Cement is a binding agent and is a key ingredient of the most used manmade material: concrete. The demand for cement is strongly correlated to the rate of economic ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ... For commercial cement plant ball mill 12 m long, ... P_Grinding_Operations_ )

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

particle size distribution effects that should be considered when performing flotation geometallurgical testing % %

This is a case study of another successful application using Belzona products

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

be applied in cement grinding optimisation. Only the cement clinker grinding is ... The "work horse" of the cement grinding plant is the twocompartment ball mill,

LargeScale Production of EdgeSelectively Functionalized Graphene Nanoplatelets via Ball Milling and Their Use as MetalFree Electrocatalysts for Oxygen .

CEMENT MILLS Twochamber ball mills for the cement ... CEMENT MILLS MILL DESIGN Out cement grinding mills are ... CEMTEC also supplies complete grinding plants.

Geotechnical Services | Piling | Geotechnical Drilling | Geotechnical Report | Geotechnical Testing

WhatsApp)

WhatsApp)