WhatsApp)

WhatsApp)

7 Chapter 2. Production and Processing of Aluminum Extraction of Aluminum The extraction of aluminum from its ore and subsequent processing into finished products takes place in a series of successive operations, each ...

Froth flotation is considered to be the most widely used method for ore beneficiation. In ore beneficiation, flotation is a process in which valuable minerals are separated from worthless material or other valuable minerals by inducing ...

Applications Steel is ideal for recycling because it does not lose any of its inherent physical properties during the process, which can be repeated ad infinitum. Steel is 100% recyclable and therefore, recycled steel can be used for the ...

Umbrella vinyl collector, stainless umbrella plastic cover collector, Easy Collection of Umbrella Vinyl, Easy umbrella cover packing and collecting, Making your entrance environment clean and neat with Umbrella cover packing and ...

Modern copper smelters use processed copper ore fed into a flash furnace, typically fired by oxygen which produces blister copper, being further processed in a converter furnace. Molten copper is poured from here into rectangular ...

BULK PROCESSING MATERIAL HANDLING EQUIPMENT Bulk material handling equipment simplifies the workintensive process of managing ingredients, parts, and other bulk materials. General Kinematics combines innovative ...

More than 3,500 items immediately available for sale for food, chemical, pharmaceutical and minerals processing industries. Browse dozens of categories for used processing and packaging machinery. View our inventory and send ...

The ore is loaded into a blast furnace along with measured quantities of coke and limestone. Hot combustion air is supplied to the furnace and some form of fuel used to raise the temperature. The iron is reduced from the ore by ...

Cartridge Donaldson Torit® advancedtechnology cartridge dust collectors and a variety of filter media that conquer the challenges of most types of industrial dusts, including pharmaceutical, chemical, grain, bulk/powder, food, metal ...

The steel plant is a lean, green, recycling machine making new steel from recycled steel scrap. Enough iron and steel is recycled each year to save the nation 74% of the energy that would be needed to make new steel.

Use of Iron Ore Pellets in Blast Furnace Burden Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then shaping them into oval ...

2012/01/01· Chalcopyrite ores are usually processed by means of hydrometallurgical or pyrometallurgical processes, but due to environmental aspects and the possibility of increased exploitation of mixed and lower grade ores and ...

Iron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then shaping them into oval ...

Bengal Aerotropolis project is being developed by a special purpose company Bengal Aerotropolis Projects Limited (BAPL). The study is for the development of the township planned to be in 2 phases covering 1700 acres of land. TCE ...

2017/08/23· Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden. Cement is manufactured through a closely controlled ...

by the way, Why do we need "Coking coal"? Because Iron ore=has iron oxide. But We''re only interested in iron. So, we''ve to get rid of the "oxide" part. Then how can we remove the "oxide" part? Ans. Make him marry with carbon and ...

In the 1800s, tin was an ordinary household material particularly popular with the working class because of its low cost and bright luster. Made of iron or steel rolled thin and dipped in molten tin, it was easy ...

Small amounts of limestone (1%) are also added and mixed with the concentrate at this point. Limestone is added to meet the requirements of steel customers in the blast furnace process. The iron ore concentrate is now mixed and ...

Dolomite and limestone are similar rocks. Both are sedimentary carbonates with many nearidentical properties. ... Dolomitization Dolomite is very common in the rock record, but the mineral dolomite is rarely observed forming in ...

Lateritic nickel ore deposits are surficial, weathered rinds formed on ultramafic rocks. They account for 73% of the continental world nickel resources and will be in the future the dominant source for the mining of nickel.

Lateritic bauxites (silicate bauxites) are distinguished from karst bauxite ores (carbonate bauxites). The carbonate bauxites occur predominantly in Europe, Guyana, and Jamaica above carbonate rocks (limestone and dolomite), where ...

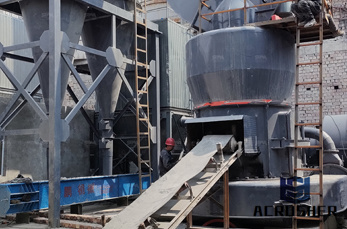

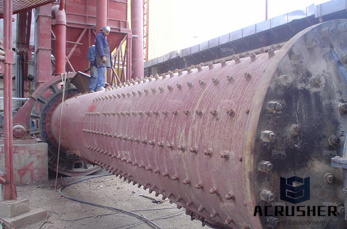

Grinding Metso Minerals design and manufacture a comprehensive line of grinding mills and entire grinding systems for mining, industrial minerals industry, coal and cement, including classifiers and related accessories for ...

Ilmenite is a black iron titanium oxide mineral found in igneous rocks and sediments. It is the primary ore of titanium. ... Geologic Occurrence Most ilmenite forms during the slow cooling of magma chambers and is concentrated ...

To a large extent, copper oxide and sulfides are naturally separated in nature. As such, once mined the processing of the ore generally does not need to separate the oxides and sulfides. Primary orebody formation Copper orebodies ...

WhatsApp)

WhatsApp)