WhatsApp)

WhatsApp)

Is dedicated to the mining of metallurgic coal that is use principally by ahmsa in the production of steel products total production 4 million tons per year la perla mines de fierro y carbon la perla is dedicated to the mining of iron ore and owns a pellet plant which is located at ahmsas steel

Crude coal tar is a by product of the coking process coking is the process of heating coal in coke ovens to drive volatile matter from it metallurgical coke is used as a fuel and reducing agent in the production of iron steel ferroalloys elemental phosphorus calcium

An adjacent thermal power plant receives fuel gas as a byproduct of the steel plant and supplies generated electricity and heat back to the steel plant most of the process systems in a steel plant are operated under atmospheric pressure and heat exchangers are not much used despite improved heat recovery systems

Jan 14 2020 today steel production makes use of recycled materials as well as traditional raw materials such as iron ore coal and limestone two processes basic oxygen steelmaking bos and electric arc furnaces eaf account for virtually all steel production

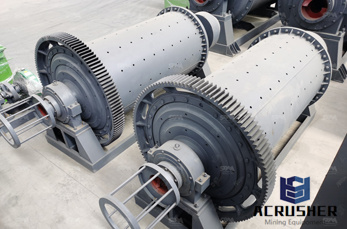

Nov 17 2012 pulverizermill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill the coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill the pulverized coal and air mixture is then transport to the boiler burner

The atox coal mill handles feed materials with less than one percent moisture and up to 25 percent moisture where abrasiveness and stickiness is not an issue for grinding longlasting durability the materials used to produce the atox coal mills segmented wear

Mar 02 2018 coal is the dirtiest fuel on the planet and emissions from its use as a source of heat and energy make it historically the single largest threat to our climate but it is also the largest source

For decades access to cheap coalfired electricity fueled industrial expansion across the midwest now missouri is planning the first windpowered steel production plant which some see as a

The cold sheet and tin mill was supplied with hot band from the lackawanna plant until the burns harbor plant hot strip mill went into production the september 1965 grand opening of the burns harbor plant was proudly described by bsc chairman edmund martin as a weeklong extravaganza costing

Oct 28 2017 a mini steel mill melts scrap to make steel typically it start with an electric arc furnace required to melt it in contrast typical integrated steel plant uses coal and iron ore as input material to make steel they have coke ovens blast furn

Iron and steel a trip inside a steel mill pure iron prepared by the electrolysis of ferrous sulfate solution has limited use commercial iron invariably contains small amounts of carbon and other impurities that alter its physical properties which are considerably improved by the further addition of carbon and other alloying elements

Nucor to build new florida steel mill as domestic producers study tariff impact chief executive john ferriola said the plant would produce reinforcing steel bars used in construction and will

The function of the coal fired thermal power plant is to convert the energy available in the coal to electricity coal power plants work by using several steps to convert stored energy in coal to usable electricity that we find in our home that powers our lights computers and

Mar 29 2017 primarily for cement grinding plants in india coal generally of bituminous grade is used in the slagdryer the wet slag arrives at the stack on wagons from some nearby steel plant or it may be brought via a trolleysystem primitive mode bu

57 union electric steel corp harmon creek plant burgettstown pa 35 58 universal stainless alloy products bridgeville pa 149 60 vm star steel co youngstown oh 694 bof ind or rolling basic steel mill products capacities only made available for melting facilites 10d evraz portland portland or 11b gerdau long steel north america

Global steel production is dependent on coal 70 of the steel produced uses coal metallurgical coal or coking coal is a vital ingredient in the steel making process world crude steel production was 18 billion tonnes in 2018

Rolling mill applications yokogawa helps leadingedge iron and steel plants through automation solutions that enable plantwide integration and lifecycle optimization here is a quick list of rolling mill units and applications for which yokogawa has a global network of experts at your service providing comprehensive automation solutions

The price of steel at the time of writing this is about 550 per ton we can estimate the production costs due to the energy required by assuming that the creation of pig iron and the basic oxygen furnace use coal or natural gas to power the process and an electric arc furnace uses pure electricity

National grid generation based on 60 percent coal 11 percent natural gas and 29 percent noncarbon resources rather than generation from 100 percent coal this would represent about 2 percent of the total annual us carbon equivalent emissions energy use in the us steel industry iii

End use of fuel consumption the manufacturing energy consumption survey mecs collects fuel consumption by end use for six major energy sources electricity natural gas coal lpg dieseldistillate and residual fuel oil coke an energy source used for fuel in a blast furnace is not included as one of the six major energy sources when collecting for end use in the mecs

Find here online price details of companies selling coal mill spares get info of suppliers manufacturers exporters traders of coal mill spares for buying in india

WhatsApp)

WhatsApp)