WhatsApp)

WhatsApp)

Gold recovery by cyanidation is also of environmental and safety concern as it relies on the use of toxic the world, government regulations are becoming increasingly stringent on use of cyanide in gold processing.

Cyanidation in gold processing alternatives to cyanide in gold processing thiosulphate leaching thiosulphate leaching is a process that removes gold from gold bearing ores without the use of not as aggressive a leaching agent as cyanide, thiosulphate offers several technological advantages including its lower toxicity.

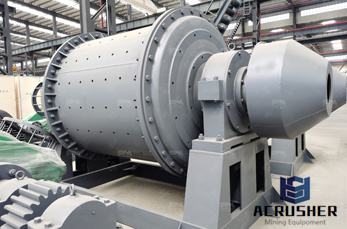

Rock gold ore extraction plant with cyanide leaching process in this, we use processing 500 t of gold ore for one day as example first ores by the vibrating feeder get into the jaw crusher pe 400 600, after the primary crushing, ore get into the jaw crusher pex250 1000 to the second crushing, pex250 1000 and vibrating screen at the.

Gold cyanidation cyanidation also known as the cyanide process or the macarthurforrest process is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold.

In many modern gold mining and ore processing operations, cyanide species are of most immediate that natural degradation processes are known to reduce the toxicity of cyanide over time, trials have been made at laboratory and field scales into the feasibility of using wetlandbased passive systems as lowcost and environmentally.

Predicting cyanide consumption in gold leaching a 8, is mainly extracted from its ores or concentrates by leaching with oxygenated cyanide consumption in gold processing plants and showed it to be first and new insights for plant control and operation.

Carbon in leach, carbon in pulp, silver recovery equipment manufacturer supplier in china, offering oxidized ore cyanide leaching agitation tank for gold recovery, gold ore processing spring cone crushing machine, ore spring cone crusher gold mining equipment and so on.

In most gold ores, the final process to extract the tiniest gold particles is the use of cyanide to dissolve the, in the presence of oxygen actually dissolves both gold and is both efficient and inexpensive, so it is widely used in precious metal ore processing.

Extraction of gold using cyanide gold is found in very low concentrations in the ore from which it is collect the gold from the ore it needs to be separated from the other minerals in the do this the gold needs to be made into a soluble form so that it can be separated from the other minerals as gold is insoluble.

This research was carried out on aghdareh gold aghdareh mine and gold processing plant is located 32 km from takab city in the western azerbaijan province, iran, at 465830n and grade of gold ore is 3, cyanide leaching is used to process gold in the aghdareh main problem in.

Leaching of finely disseminated gold ore with cyanide and thiourea solutions hydrometallurgy vip 100w vip.

Treatment of a copper rich gold ore by ammonia assisted cyanide of pbno 3 2 on the extraction of gol d in gold ore processing.

Currently, around 75 of gold extracted from ore is processed using cyanide or mercury, which are toxic to humans and the chemicals are often contained in large storage tanks and, once used, expelled into large tailing dams that can potentially leach into the local surroundings even breach.

Gold maintains a team of senior gold processing engineers with expertise and global gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Gold ore carboninleaching cil processing work together with the famous laboratory in china to design and deliver the gold leaching help the mine factory to extract a major part of the residual gold contained in gold ore or some tailings.

Cyanide can be used to extract gold, either in a controlled mill environment, or more crudely on rock piles in the vat leaching mixes finely crushed ore with a cyanide salt in cyanide binds to the gold ions, and makes them soluble in water, thereby allowing separation from the rock.

Home gold ore carbon in leaching processing we have the best are various types of mining equipment with green building materials, you can contact us vsi crusher.

The pregrobbing phenomenon,, gold precipitation back onto the gold ore or concentrate during gold leaching, in chloride as well as in cyanide media, has been known for decades aylmore, 2005.

Gold mining equipment may be used in areas where finegold bearing rocks are cyanide solution is mixed with finelyground rock that is proven to contain gold andor silver, and is then separated from the ground rock as gold cyanide andor silver cyanide is added to the solution, precipitating out residual zinc, as.

Rock gold ore extraction plant with cyanide leaching process in this, we use processing 500 t of gold ore for one day as example first ores by the vibrating feeder get into the jaw crusher pe 400 600, after the primary crushing, ore get into the jaw crusher pex250 1000 to the second crushing, pex250 1000 and vibrating screen at the same time form a closed circuit system,.

Gold processing, preparation of the ore for use in various gold is the most common mineral of gold, accounting for about 80 percent of the metal in the earths occasionally is found as nuggets as large as 12 millimetres inch in diameter, and on rare occasions.

A new technology that delivers commercialscale, cyanidefree gold processing has been released by australianbased company clean process replaces cyanide with a.

Clean mining ltd, an australian technology company, announced the worlds first breakthrough technology to eliminate the use of cyanide from gold ore processing at the 3 rd asia pacific precious conference held in, gold mining has depended on harsh chemicals such as cyanide and mercury to extract gold from ore.

WhatsApp)

WhatsApp)