WhatsApp)

WhatsApp)

SUMITOMO KAGAKU 2007II 2 Design Method of Ball Mill by Discrete Element Method of the balls are in a state where they are covered with the solid materials.

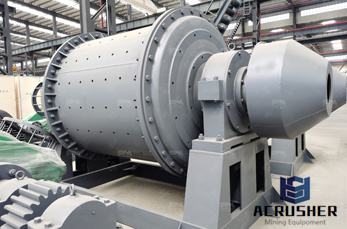

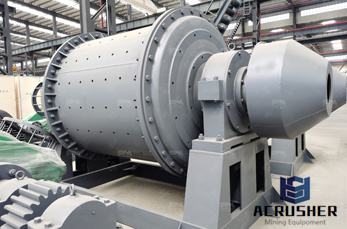

Versatile system based on standard modules 2 The FLSmidth ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Calculations for mill motor power, ... the motor power required for a cylindrical type ball mill, ... Required motor power in HP : D = Internal dia of the mill in mtr :

Ball Size Eqn[1] ball mill ball size calculations. wheel turning torque calculation. . Calculation of power consumption for ball mills and grinding media charges .

Ball Charge Loading Impact on Specific Power Consumption and ... research concludes that lowering the ball mill filling percentage negatively affects mill ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly depending on the size, ... the mill shaft power and

grinding mills. Grinding mills supplied by FLSmidth ... renowned SAG and Ball Mills ... power draw on larger mills

Calculated Power For GrafeDischarge And Overflow Ball Mills. ... – Calculation of power . Ball mill critical speed, Ball mill efficiency,ball mill media. ...

evolved in size, power draw and durability for over a century but the technology has ... Primary Rod Mill followed by Secondary Ball Mill Figure 4.

Ball Mill Design/Power Calculation Mineral Processing . The basic parameters used in ball mill design ... (ball mill capacity calculation)XSM also supply individual .

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and .

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen ... cement industry the ball mill was really an epochmaking breakthrough as for almost

parameters are inputted for the speci c power calculation. ... No 1 rod mill/ball mill circuit was operating very effi ciently

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

· Ball mil design calculation? ... The output achieved by a ball mill system varies with the mill power, ... I need a design calculation of continuous ball mill?

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... Figure Simplified calculation of the torque required ... Figure Effect of mill filling on power draft for ball

The most important concept in the Attritor is that the power input is used directly ... The critical speed of a ball mill is calculated as divided by the square ...

Mill power calculation. The Cement Grinding Office. The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses;

Notes on Ball Mill Design Power Draw. Power Draw is steady running power requirement ... ignoring drivetrain losses and startup loads. Power Draw is reduced for ...

16 Ball Filling Degree Mill Calculation. ... Relative mill speed Factor Media weight Motor power abs. Spec ... Ball_mill_Finish Mill Ball Charge Calculation.

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

201699 · cement mill power calculation ... (or finish mill in North American usage) is the equipment used to grind Cement Ball Mill Power Calculation ...

The quantity of material that bypasses the ball mill power calculation depends on the method used to simulate the phantom cyclone, but in general, ...

WhatsApp)

WhatsApp)