WhatsApp)

WhatsApp)

The latest news, articles, and techniques in mineral processing for the mining industry from accelerating science by thermo latest news, articles, and techniques in mineral processing for the mining industry from accelerating science by thermo step between mining iron ore and are miners reading on.

in october moved to idle line 3, one of its five pelletizing lines at minntac, citing soft market minnesotas six iron ore mining and processing facilities produce iron ore pellets that contain pellets are fed into blast furnaces at.

2 the nullagine iron ore deposit is located 140km north of newman in the pilbara region of western is developing a rail line near christmas creek, which can be accessed via the private haul road, to transport the nullagine iron ore.

Metso minerals will supply a complete processing system for copper ore beneficiation to zinkgruvan mining ab for its mine in southern delivery will.

Liquid line magnetic separator the liquid line magnetic separator is a specially designed compact inline magnetic separator for removing tramp iron from liquid stream very fine particles may be mixed up in the production line which may be due to wear and,hammer iron ore magnetic separator processing line.

At the processing plant, the taconite is crushed into very small pieces by rock crushing crushers keep crushing the rock until it is the size of a rock is mixed with water and ground in rotating mills until it is as fine as the iron ore is.

Northshore operations consist of an open pit truck and shovel mine where two stages of crushing occur before the ore is transported along a wholly owned 47mile rail line to the plant site in silver the plant site, two additional stages of crushing occur before the ore is sent to the concentrator.

The entire processing line can be planned in semimobile form and consists only of crushers, screens, belts and sorting all of the improvements ore sorting technology has brought to the mining industry, effective ore sorting on a bulk scale is still some way away.

The first plant to be commissioned was a 700 tph plant at the iron baron mining site, while the second was a 250 tph plant at the iron knob mining site both processing the low grade iron ore stockpiles accumulated over the operations life.

Operations consist of an open pit truck and shovel mine, a concentrator that utilizes single stage crushing, ag mills, magnetite separation and floatation to produce hematite and magnetic concentrates that are then supplied to the onsite pellet plant.

Xinhai epc provides services of sample test, mine design, equipment manufacture, clients, and solves the common problems in plant construction such as budget overrun, schedule delays, unqualified equipment, unclear recovery benefit, disputes of the manufacturers, and unclear responsibility of.

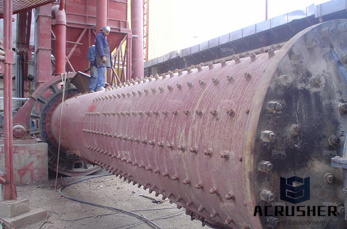

Reliance steel technology is your one stop for expert engineering in mining and mineral processing, improvement, update technology and research and us for our full line of mining and mineral processing parts like rod, ball and semi autogenous grinding mills.

How much cost of 300tph flotation separation line introduction flotation plant is also called flotation separation separation plant can be classified into copper ore processing plant, iron ore processing plant and tin ore processing major components continue reading.

Our company,shandong huate magnet technology co.,ltd specialized in the complete ore processing line and manufacturing of iron separation on rich experience, wellestablished customer, advanced manufacturing equipment and strength.

Iron ore mining ores are rocks and mineral deposits from which clanging iron can be reasonably ores are generally prosperous in iron oxides and fluctuate in color ranging from dark grey, bright yellow, deep purple, to even rusty red.

America iron ore mining ore crusher plant processing generally includes exploration, mining, crushing, screening, and dry, transport and other iron ores are crushed by jaw crusher in the primary crushing, and then we will get a reasonable degree of fineness iron ore.

Its all about the iron ore industry, you want the largest possible throughput of iron ore through your processing why you need the most reliable and proven equipment that never lets you down, even though it handles large tonnages every day of the year.

Mining and ore processing equipment for iron ore, bauxite, chomite and other mineral ores.

The simandou iron ore project is located in eastern guinea, approximately 600km from the guinean coast and 400km from the liberian courtesy of rio first shipment of iron ore from simandou is expected in courtesy of rio is the concession licenceholder of the simandou iron ore project.

Mining and processing for eliwana iron ore openpit mining method, involving drill and blast in addition to load and haul, will be applied at will undergo primary crushing before being forwarded to the ore processing facility opf through an overland conveyor.

Develop new products development is a key part of gme culture since it was rd team is made of 78 senior engineers.

The customer is an iron ore production line invested by a wellknown local mining company has strong strength and rich production line adopts the europeanstyle jaw crusher with advanced equipment is running stably and the output is up to owner is very location china neimenggu.

Magnetite iron ore citic limited, through citic mining international, has the right to mine 2 billion tonnes of magnetite iron ore at cape preston, in western australias pilbara region, and has exercised the option to acquire an additional one billion tonnes.

When europeans began working the metal, their processing methods removed the result was a soft metal that could be shaped, or wrought by assembly line image via is the oldest and largest iron ore mining company in the united states of america.

WhatsApp)

WhatsApp)