WhatsApp)

WhatsApp)

The Selection and Design of Mill Liners. ... especially of large SAG mills, ... Integral wave blocks – These are commonly used in ball mills, ...

For AG/SAG mills, this may result in a ... The design of rod and ball mills is still ... SAG Mill Testing Test Procedures to Characterize Ore Grindability ...

All of the ..... semiautogenous grinding (SAG) mill, 2 ball mills, 6 ... terminations, 21,000 of metal cable support trays,. CHAPTER ONE Home Citas University

It is a frequency work to maintain and repair ball mills, AG mills and SAG mills.

EURASIAN MINING • 1. 2015 Technology and technics of ore preparation processes 7 feed for the rod mill, 10000 μm in accordance with Table.

Mill (grinding) – Wikipedia, the free encyclopedia. It is similar in operation to a SAG mill as described below but does not use steel balls in the mill. .

SAG Mill Parts Ball Mill Wearparts CustomFit to Suit. Unicast SAG mill parts and Ball mill wearparts include liners from Feed Head to Discharge End, Head Liners ...

PERFORMANCE ENHANCMENT TOOLS FOR GRINDING MILLS 103 ... SAG and ball mills have grown in size and there are now many operational mills in the range of 28–40 .

Model Predictive Control for SAG Milling in Minerals Processing Steven J. McGarel, Rockwell Automation Introduction SAG and ball mills are generally accepted as the ...

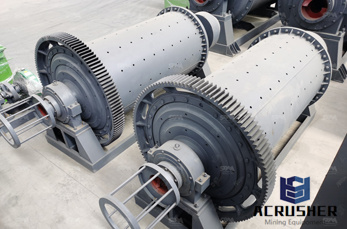

Our ball mills are perfectly suited for the preparation of hard and very . ... sag mill grinding design versus geometallurgy – getting it right for .

· sliding bearings are replaced by double row roller bearings in small and medium size ball mills to reduce energy consuming

forged steel balls in SAG and Ball Mills, Steel Ball, Mill . Import forged steel balls in SAG and Ball Mills directly from China factory, Shandong Huamin Steel Ball ...

grinding mills. Grinding mills supplied by FLSmidth have their origins dating back to the ... renowned SAG and Ball Mills operating in some of the most

SAG and ball mills are generally accepted as the largest power consumers in a mining and . Different types of mill are in operation rod or ball mills, ...

peening on the liner plate as well as minor ball and liner breakage occurred. SAG mill speed was thus lowered and charge level raised until

COMMINUTION ''10 Capetown, SA John Starkey1, ... to 40 ft diameter in multiple SAG mills, and ball mill sizes varied from 7 ft to 27 ft in diameter.

FLSmidth ball mill for cement grinding. ... compartment ball mills is of a rigid design and is supported on a ring of cast steel segments that are bolted

Autogenous mills, semiautogenous mills and ball mills for wet grinding. ... supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating

A general model for semiautogenous and autogenous milling. ... for SAG and FAG mills, ... the design of ball mills has advanced (1)

ARE SAG MILLS LOSING MARKET CONFIDENCE? ABSTRACT Autogenous ... and opted for a single SABC line with one 20 MW SAG mill and two 8 MW ball mills, which .

SAG is an acronym for SemiAutogenous Grinding. SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill.

stage ball mills, rod mills or AG/SAG mills when calculating power according to the Bond Third Theory method. Rod mill and AG/SAG mill products are similar and tend to

large sag and ball mill drive systems. sag mill and ball mill lubrication system flow circuit design ... Ball milling and rod milling,Milling Equipments use Wet rod ...

Sag And Ball Mills Principles Of Sag And Ball Mill Operations. principles of sag and ball mill operations Grinding Mill China ; Principle of SAG Mill ...

WhatsApp)

WhatsApp)