WhatsApp)

WhatsApp)

At Arrow Grinding, a complete quality process is in place, from the point raw materials are received to the finished delivered parts. Learn more.

BALL MILL. GRINDING 1 Ball Mill Grinding LEARNING OBJECTIVES At the end of the day the trainee shall be able to : Describe the ball mill grinding process

The Drum Mill TM 300 XL allows powerful grinding of ... The grinding process is ... separation grid to separate sample from grinding balls (only for Ball Mill)

Union Process offers a full line of high quality grinding media balls, engineered to meet your most demanding milling applications.

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

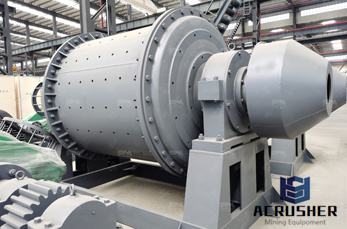

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

The DMQX bead mill from Union Process provides highly effective, reliable circulation grinding, producing uniform fine dispersions with superior product quality.

World Least Wear Rate High Chrome Cast Grinding Ball Supplier

Primary Grinding Process Ball Mill Roller Mill, Find Complete Details about Primary Grinding Process Ball Mill Roller Mill,Ball Mill,Grinding Mill,Grinding Ball Mill ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause .

Kinds Of Grinding Mills, Grinding Machines,Grinder For Sale! Want Grinding Minerals into fine Powder? Contact now, The Biggest Grinding Mill Manufacturer In China ...

About Us. Mcguire Grinding Inc is a service company providing extreme precision grinding to our customers. We are equipped with 14 Centerless grinders Full support ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

Versatile system based on standard modules 2 The FLSmidth ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Used Mills for the Chemical, Food, and Pharmaceutical Packaging and Processing Industries Used Mills from Special Projects International

Figure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate)

STR Industries is an manufacturer and supplier zirconia ceramic grinding media for mixing, crushing, dispersing and purifying variable materials.

Lab Grinding Mills In a laboratory setting, most materials used for sampling are nonhomogeneous mixtures. The best method of obtaining a small sample of these ...

Find great deals on eBay for ball grinding mill and potassium nitrate. Shop with confidence.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Ball mill is widely used in powdermaking production line of cement, ... There are two ways of grinding: dry way and wet ... thus the grinding process is finished ...

WhatsApp)

WhatsApp)