WhatsApp)

WhatsApp)

Chapter3 cement manufacturing process 38 this area of the kiln is called the burning zone where the temperature is about oc the hot gas generated in the burning zone of kiln is sucked through a preheater cyclone by a fan called preheater fan which also creates a

So2m 3 the bat emission level2 associated with these techniques is 200400 mg so 2m 3 so2 emissions from cement plants are primarily determined by the content of the volatile sulphur in the raw materials kilns that use raw materials with little or no volatile sulphur have so2 emission levels well below this level without using abatement

Automation of a multiple kiln plant gino bittante vp lime and cement universal dynamics ltd canada and john kay president universal dynamics technologies inc formerly process automation systems inc canada describe the installation cutover and initial running of a computer monitoring and control system in a multiple kiln plant the

Emissions of so2 nox and pms from cement plant in vicinity of khoms city in north western libya december 2012 indian journal of environmental health

Process compatible so2 control in cement kilns process compatible so 2 control in cement kilns by david gossman introduction on september 9 2010 the us epa finalized new emission control regulations that include new nsps regulations on no x and so 2 for all cement kilns that began construction reconstruction or modification after june 16 2008

How to control fugitive dust emission in cement plant fugitive dust in cement plant is one of the biggest problem cement plant already using bag house esp dust suppression methods but the

potential so 2 control techniques evaluation of so 2 control techniques applicable to cement kilns portland cement and its manufacturing process although the two words cement and concrete are used interchangeably in common parlance portland cement is actually one of the ingredients composing concrete concrete the widely used

Available and emerging technologies for reducing greenhouse gas emissions from process kilns in operation in the us long dry ld kilns preheater ph kilns and additions of approximately 5 percent gypsum to control the setting properties of the cement can be done in ball mills ball mills in combination with roller presses roller

Process compatible so 2 control in cement kilns by david gossman introduction on september 9 2010 the us epa finalized new emission control regulations that include new nsps regulations on no x and so 2 for all cement kilns that began construction reconstruction or modification after june 16 2008 since any recently built plant will be a

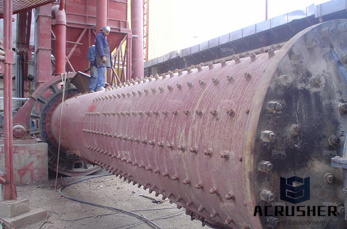

Process monitoring at the rotary kiln cement clinker quality is highly dependent on the process conditions inside the rotary kiln performing gas analysis in the rotary kiln process provides the opportunity to optimize oven firing and the burning process as well as to prevent blockages in the kiln

In the causticizing plant of the kraft recovery process many of the problems encountered in lime kiln operations can be related to kiln chemistry including trs and so2 emissions dusting ringing and refractory brick thinning suitable for use in kiln control since it represents all types of sodium in the mud 00 02 04 06 08 10 12

Cement rotary kiln questions answers question1 what is the maximum continuous shell temperature a kiln oxygen enriched combustion air in the clinker burning process allows an 2 emissions so far but the use of enriched combustion air may result in fuel savings and thereby avoids co 2 production the decision for a dedicated

Process compatible so 2 control in cement kilns by david gossman introduction on september 9 2010 the us epa finalized new emission control regulations that include new nsps regulations on no x and so 2 for all cement kilns that began construction reconstruction or modification after

2 cement production also is a key source of co2 emissions due in part to the significant reliance on coal and petroleum coke to fuel the kilns for clinker production globally co2 emissions from cement production were estimated at 829 mmtco2 in 2000 7 approximately 34 of global co 2

Compatible with most other plant control systems flsmidth the process knowledge experts flsmidths international team of process experts designs solutions specifically for cement applications with more than 40 years of plant automation experience flsmidth has installed over 700 control systems and 450 laboratory systems and

Aug 09 2018 ring buildups in kiln section part1 the rings and buildups are accumulations of solid materials in the rotary or static sections of the kiln ring and buildup formation in cement kilns and preheaters has very bad influence on cement manufacturing process decrease or stopping the clinker production there by increasing the production costs the consequence

Re so2 emission control hello tam so2 emissions in a properlyoperated cement kiln with a reasonable alkaliso3 balance are due primarily to increased levels of sulphides and organic sulphurcontaining compounds in the raw meal

22 nox control technology for cement kilns nox control approaches applicable to the cement industry may be grouped in three categories process modifications where the emphasis is on increased energy efficiency and productivity combustion control approaches where the emphasis is on reducing nox formation and nox reduction controls which

New technology for cement plant kiln capacity11000th feeding cement manufacturing ponents of a cement plant this page and the linked pages below summarize the cement manufacturing process from the perspective of the individual ponents of a cement plant the kiln the cement mill etc for information on materials including reactions in the

Aug 30 2012 cement manufacturing process phase iv kiln phase kiln is a huge rotating furnace also called as the heart of cement making process here raw material is heated up to 1450 c this temperature begins a chemical reaction so called decarbonation in this reaction material like limestone releases the carbon dioxide

Process compatible so 2 control in cement kilns by david gossman introduction on september 9 2010 the us epa finalized new emission control regulations that include new nsps regulations on no x and so 2 for all cement kilns that began construction reconstruction or modification after

Thc control using existing cement kiln particulate control equipment dioxinfurans 02 ngdscm 3 cement kiln mercury control 4 options for hg control 1 shutdown 2 change raw materials andor fuels 3 add a polishing baghouse and sorbent injection process the pac sorbent so that it does not interfere

Cement kilns are the most common users of hazardous wastes as blending fuels cement kiln energy recovery is an ideal process for managing certain organic hazardous wastes the burning of wastes or hazardous wastes as supplemental fuel in the cement and other industries is not new

WhatsApp)

WhatsApp)